During the pandemic, I decided to build myself a 3D printer to add another dimension to DIY projects. As for this post, here are some pictures I clicked along the way. I built this printer at a time when I was loaded with college assignments, else all of it could have been done in 3-4 days! Ended up working for just about 1 -1.5 hrs a day.

09/11/2020 – Fixed the frame to the base and got some parts 3D printed from another local vendor.

10/11/2020 – Assembled the Y-axis mechanical structure, consisting of smooth rods and the print bed.

14/11/20 – Assembled the Mk8 extruder attached it to the X- carriage using zipties.

14-17 /11/20 – The z-axis simply wouldn’t work and make screechy sounds during the print. Tried all I could to debug it. Luckily someone on Reddit was able to point out that my Z-axis homing speed was too high. It was time for the first print, which took quite some time to tune…

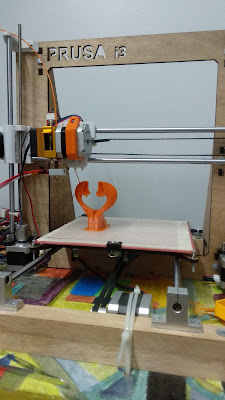

19/11/20 – And the printer worked perfectly! It was time to replace Zipties with decent looking plastic parts. I found a nice extruder mount on Thingiverse and printed it out.

21/11/20 – The very next thing I wanted to fix was the spool holder. Until then, the filament was in a box and would pull it out to create some slack every 5-10 mins. I used some old PVC pipe lying around in the house and bought a few joints to make a decent spool holder.

13/12/2020 – Had lots of fun printing keychains, gears, and other small stuff. Also printed a guitar capo that worked wonderfully!

I realized that 5mm threaded rods on the z-axis had started to bend forwards. After a bit of googling, I got to know that most designs today, use either 8 or 10mm leadscrews. I stupidly dismantled the X-axis before printing parts for the new X-Axis. So once again, asked my local vendor to print some parts for the new X-Z axis.

01/02/2021 – No problem with the printer, but I guess most projects such as the BCN3D moveo require a bigger print bed, so I plan to rebuild the frame with a bigger bed, preferably using aluminium extrusions!

Leave a Reply